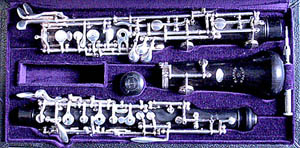

Current Models

Interview with Alain and Robert De Gourdon

July 7, 1982 Paris

by NORA POST

|

|

For most of us, the firm of F. Lorée needs no introduction. The Lorée oboe is as much a part of oboe history -- and our professional lives -- as anything could be. Interviewing Alain de Gourdon, the current director of F. Lorée, my admiration for his skills and dedication to a superior product only escalated. While Alain and I were talking after the interview, he commented on an extremely expensive piece of machinery which probably wasn't needed at the time of purchase, but which he felt would be a good investment in the long run. He put it this way: "I'm not making oboes for me; I am thinking about after me. I am making oboes for posterity." My only regret is that posterity is a long way off, and Alain de Gourdon's version of it sounds too interesting to miss.

NP: For me, this interview is an anniversary of sorts. Exactly ten years ago--almost to the day--was when I first walked through the door here. And here we are, a decade later. But let's begin. Could you tell me exactly what your responsibilities are?

AG: The biggest part of my work is to control all aspects of oboe production; I also do the final adjustments. I used to do more of the manufacturing myself-- drilling the tone holes for instance -- but I don't have the time for that now, since I have forty people working for me. There are always problems which need my attention. I also spend a lot of time with customers, and my sister and I spend time with the financial aspects of the business. We must also correspond with many, many people.

NP: When did you begin making oboes?

AG: 1967. I tried to learn a little of everything, though I did not have a complete apprenticeship. My father was ill in 1967, and for three weeks there was no boss. So I had to accept responsibility immediately. Since every job in making an oboe is specialized, if I really apprenticed, it would have taken twenty five years to learn to do it as fast and as well as the people who do all those jobs.

NP: Do you have an official position within the firm?

AG: Yes. I am a sort of director. Though really, sometimes I am not sure what I am! If a worker is absent, for instance, I will often do part of his job. I work in three places, too -- we have two factories outside Paris. So I must coordinate the activities of all three locations -- I spend at least one day a week doing just that.

NP: What was your education like?

AG: Well, I completed two years of work in accounting before I started to work here in 1967. I learned everything about oboes right here. Since I am thirty-three years old, that means I've been here for fifteen years--a long time!

NP: As I was walking in, I heard you practicing. When did you begin the oboe?

AG: At twelve. I studied until I was eighteen or nineteen. Then I won my prize at the Versailles Conservatory. I still try to play a little every day, though it's very difficult to play oboe and make oboes. I continue to test all the oboes, but technically I'm not really so good! My technique is definitely not wonderful.

NP: Do you find that being able to play the oboe is helpful to you as a maker?

AG: Yes, certainly. When I do the final tuning, I must play the oboe myself, in order to be sure of what stays the same and what must change. And before you tune the instrument, you must be sure of the covering, the springs, the opening of the keys; otherwise you are tuning when part of the oboe isn't finished, and you make a bad instrument.

NP: Do you do the tuning on the English horns and bass oboes, too?

AG: Yes. Our bass oboe is a copy of an old Lorée instrument, but I have made changes in the bore, tone holes, mechanism design, and I've done experiments with bocals. So far, people seem very happy with it. I'd like to make a musette next, to complete the entire oboe family.

NP: Sounds great. Though I'd like to change the subject to production for a moment. Can you explain the stages of production for a Lorée oboe, and where each takes place?

AG: We have a factory in Ivry la Bataille, about one hundred kilometers west of Paris, where the wood is turned and aged for five years. It's a small factory--three people--and this is the only work they do. We couldn't do that here in Paris because we don't have the space for it, plus we could never get a permit because of the dust and noise pollution. The keys are made and mounted at the other factory in Magnanville (near Mantes), about fifty kilometers west of Paris. We make our keys out of nickel silver sheet metal, using a press and cutters. Then we bevel and shape the keys before doing the mounting on the wood.

NP: How many people work at the Magnanville factory?

AG: About eighteen. We also have about fifteen people who work at home. We are forty-two altogether. The people who work at home do the keywork and the finishing -- corks, springs, screws, getting all the keys to work. And Mantes is a bit like Elkhart, Indiana -- an area where it's easy to find workers, since the industry has been there so long (Buffet clarinets and Selmer saxophones are also there).

NP: Speaking of the U.S., I assume it's your best customer.

AG: For sure. England is good, too, and so is Japan, Korea, Switzerland and Holland. We sell a bit in Italy, and Germany keeps getting better. In South America, Mexico is the best, and then Venezuela. We also sell in Brazil, Argentina, Chile, Ecuador, and Peru. . .

NP: What percentage of your production goes to the U.S.?

AG: American and Canadian sales are about 50% of our total. England, Japan, and Germany are each about 10%. The only country I don't sell much to is France. But our French market is getting better; maybe some of the French musicians are not happy with what they are playing, and we hope that someday they will play Lorée!

NP: Do you make all your oboes at 440?

AG: No. For two years we've had what I call the High Pitch model, which is mostly for Germany. It's at least 445, and several oboists of the Berlin Philharmonic have these instruments. For the English horn, I just make short bocals and sometimes change the bell in order to play higher. The same for the oboe d'amore. But for the oboe, our High Pitch model is absolutely necessary -- and it seems to be very popular.

NP: Since so much of your market is outside France, I'm curious about what percentage of your oboes are sold right here in Paris.

AG: A maximum of 30%. And that's a big part of my work, too.

NP: There are people who might feel that it's a dangerous tactic to sell 50% to one market, in this case, the U.S. How do you feel about this?

AG: Yes, it's a problem. But I don't think I can lose my American market. If for some reason the demand was less in the U.S., I think the demand would be less in the other countries, too.

NP: How interested are you in developing your non-American markets?

AG: Of course we make efforts to sell to other countries. But I myself prefer the American style of oboe playing. Other players know my preference, and this may work against me. Recently, in fact, some French musicians asked me if the factory was French or American. Since we sell so many oboes to the States, they didn't know! But I like America, and I like the people, the mentality. It is a difficult market, but people always have interesting new ideas. I like that. And our instrument is made to be played with an American reed, though it certainly can be played with something else.

People say Rigoutat is for the French, Marigaux is maybe for the Germans, Lorée is for the Americans. They like to put people in boxes. Well, if that is so, then Lorée is in the biggest box!

NP: Yes. I haven't asked you one other question I meant to ask earlier: how many instruments do you make in a year?

AG: About a thousand.

NP: How about plastic oboes?

AG: About two or three a month. Sometimes we make rosewood oboes, and I'm planning to make a few in boxwood.

NP: How long is your waiting list these days?

AG: About a year, but we try to help people if there's a special reason why we should try to get an instrument to someone sooner than a year.

NP: How often do you make a very special oboe ?

AG: We make special oboes quite often. We make very special oboes once or twice a month, depending upon the requests. For example, right now we have orders for ring system oboes. So, after an interruption of about forty years, we are going to make them again. Recently we also made an English horn with an unbelievably complicated key mechanism based on a photo of the original! We will make anything anyone wants. We charge more, but we still lose money because of the time spent. If someone has a good reason for having something different, we will do it, and I don't care that we lose money. In fact, I would prefer to make an automatic octave system bass oboe than just to make more serial (i.e. production) oboes.

NP: Your mention of production reminds me of another question I have: what happens to an instrument after it arrives here from the factory at Mantes?

AG: My father and I finish the bore and do the final sizing of the tone holes. Then we do all the finishing and playing, of course. Only my father and I do this work.

NP: I'm laughing because Rigoutat is exactly the same way. Only the father and son.

AG: Yes. If I didn't have time to do one other thing, I would finish the bore. Even at the factory, everything in the bore is checked millimeter by millimeter.

NP: Incidentally, do you make your own reamers?

AG: No. A machinist does it for us--made to our special measurements, of course.

NP: How many oboes do you make at once?

AG: Twenty or twenty-five. We don't want to make more than that because it can become less precise. Everyone has a maximum.

NP: I see. This reminds me of something else I want to ask: how do you train your workers?

AG: They have a two-year apprenticeship here, but it really takes three or four years to train them.

NP: How many people work on an oboe from the beginning to the end?

AG: Well, there is the wood turner who makes the rough bore, and the one who drills holes for the tone holes and the posts. Then someone puts on the posts, someone files the keys, someone does the mounting for the keys, someone prepares the keys to be silver plated, someone does the springs and screws, someone does the silver plating, and someone buffs and polishes the silver (by burnishing). Someone else undercuts the tone holes, who also polishes the wood and finishes the tone holes, stamps the oboe and gives it a number, and then there's a finisher who puts it all together. Either my father or I finish the bore, control the size of the tone holes, and play the oboe. So about ten to twelve people work on each oboe.

I work very closely with my workers. We work well together, but I want only the best workers. We try to give our workers the very best salary we can. But I am very demanding and they must all give their very best. That's an important part of my work -- to make people understand that doing it well is so important.

NP: What do you enjoy the most in your job?

AG: I enjoy being with my workers. I like having the factory working well, to make a good product. It's easier to make an oboe yourself, because you know you can do it well. But to have these things done by someone else is difficult, and it's a real challenge. I like making new systems, and I enjoy seeing people's problems in playing in order to find new solutions. These players want something else, and that is always interesting. If someone has been to the other factories, still doesn't have an answer, and if I can do better, then I'm pleased.

NP: What's the worst part of your job?

AG: When I must tell a worker that he isn't good enough, and must fire him.

NP: Do you ever have problems with customers?

AG: No, never. Of course, some are difficult to please because they know what they want, and they want a great deal. But that actually pleases me. I try to deal with people who aren't that concerned with the price of an oboe, people who want something really good. And I like people who can tell the difference between a good oboe and a bad oboe!

NP: You know, I once talked to a maker of early winds who said the ideal customer for him was the rich doctor or dentist who couldn't play well, but would pay a lot for a beautiful instrument. You wouldn't agree, would you?

AG: No, not at all. I am happiest when a player has had a problem with his instrument and I can fix it, or make a better instrument. In fact I would be happy making oboes for the best players even if I weren't paid!

NP: Incidentally, who decides the price of a Lorée oboe?

AG: My sister and I. But if I decided, for instance, that solid sterling silver keys are better, I would just go ahead and do it, and raise the price accordingly, because it would be a better instrument. At the moment, a Lorée oboe costs about 9,000 francs. With the dollar at seven francs, that's not too much.

NP: Yes, it's a great time to buy an oboe! But I like what you are saying, which seems to be that the player who is considered too difficult to please is exactly the person you want to see.

AG: Absolutely. Yes. I like the people who say they have tried everything and now they come to us. And for me, it's just not enough to do the same thing we did two years ago--I want to make new things.

NP: How often do changes take place?

AG: Constantly! We are always making little changes. And I like buying new machines, too. We have wonderful machines--the best possible to buy. There's one other thing I want to say, even though some people may not understand it. If we have a certain quality today, it's because a lot of things are not made by hand. But this is difficult to explain to people. The great ads for everything from pens to musical instruments say that everything is done by hand. Of course, it's not true and, if it were, the price would be terribly high, and the quality would be lower, because machines are much more exact for certain things. An oboe today is much more precise than it was ten years ago though, of course, all the finishing of an oboe must be done by hand --corks, springs, etc. And this is all done by one person. We could have one person finish the upper joint, since it's a little easier, and another do the rest, but no, I don't want to do that. For the mounting and the finishing, each person must be responsible for an oboe.

I think next year's oboes will always be improved. I don't want to say, "This is it." After all, we're in 1982.

NP: Agreed. Being in 1982 reminds me of a historical question I'd like to ask: do you have any idea when the first Lorée oboes were sold to the U.S.?

AG: Yes. I found some old papers, and it was 1882 or 1883. The very first Lorée oboe, A-1, was sold in 1881 to the English flute maker Rudall-Carte. So we were international from the beginning!

NP: Of course, Leon Goossens plays on a very early Lorée.

AG: Yes. 1907.

NP: How about Tabuteau?

AG: Well, my father worked a lot with him, and so did my grandfather, Mr. Dubois, but it was mostly my father who worked with him. Tabuteau was responsible for the development of Lorée sales in America. My father spent days and days with him.

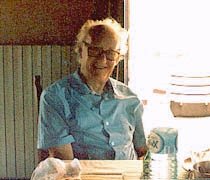

[Mr. Robert de Gourdon joined us at this point in the interview.]

RG: Tabuteau, yes. Tabuteau came to explain what he wanted in an oboe, to search for a special sound, a special sonority.

NP: What kind of changes did you make together?

RG: We changed the bore a little. We made a smaller bore to give the bigger sound that Tabuteau wanted. The smaller bore gives you a richer or bigger sound, but sometimes the pitch is lower. We are talking about the years from about 1960 to 1965, when Tabuteau wasn't in Philadelphia any more; he was in the south of France, in Nice. So he didn't care that much about the pitch! He was working just for himself. Though it may have sounded wonderful, the pitch could have been as low as 435.

NP: When did you work with Tabuteau for the first time?

RG: 1949. I came to work with Mr. Dubois when Alain was born. Of course, Mr. Lucien Lorée and Mr. Dubois worked with Tabuteau before the war --the late thirties. Even though I didn't work with oboes at the time, I knew Mr. Tabuteau since about 1934.

AG: Of course, Tabuteau worked with quite a few oboe makers. My father worked the most with Tabuteau after 1957, when my father became the director of the factory.

NP: Did Tabuteau contribute a great deal to the development of the Lorée oboe?

RG: Certainly. It was because Tabuteau played Lorée that all his students did; for Tabuteau, Lorée was the best oboe maker. Tabuteau tried everything, but he finally played Lorée. In fact, he had several oboes from Mr. Strasser at Marigaux--about 1965, I think.

NP: Did Tabuteau ever play Rigoutat?

RG: No. Tabuteau was very strong-willed, and I think he went to Marigaux after we had a little disagreement. I think he wanted to show me that it was possible to play another oboe! But it only lasted two or three months. In fact, I worked on one of those oboes. Tabuteau thought it was much better after I finished with it, but he finally decided to come back to us anyway. Aside from our argument, Mr. Strasser was a good businessman, and I think he practically gave those oboes to Tabuteau.

AG: Yes. For Marigaux, it would have been wonderful to have Tabuteau as a customer.

RG: At that time, all the Americans were very surprised that Tabuteau had a Marigaux, since he'd always told them Lorée was the only oboe.

NP: Incidentally, when during those years did the American market grow so much?

RG: 1960 or so. But in those days we couldn't make as many oboes as we do today.

NP: During the late forties, what percentage of your oboes were sold to the U.S.?

RG: 80%. Maybe even more.

NP: And before the war?

RG: Well, before the war, many of the French players went to American orchestras and introduced the Lorée oboe -- Andraud, Dandois, Fernand Gillet, and others.

NP: Of all the players who have worked with Lorée, is there anyone whose influence was greater than all the rest?

RG: Yes. Georges Gillet. He changed the ring system to plateau system sometime around 1900. Gillet created the plateau system with Mr. Lorée, but there were very few people in the world making oboes at that time. There was no Rigoutat or Marigaux. Rigoutat began, in fact, as a worker for Lorée. The only competition in the early years was a firm called Robert, which started about when we did, and lasted until 1920.

NP: Interesting. To finish up, though, I'd like to ask just one more question about Mr. Tabuteau. How much time did you spend with him?

RG: He would come during his month-long vacation. He would arrive each day. He would try oboes, make reeds, suggest changes, etc. This was when the Casals Festival was in France, so he was here each year for that. That was in the late fifties, when I had first become director of F. Lorée. So it was an important time for me.

AG: It was work for both of them. Tabuteau was here all day, and at night my father had to make oboes! Also, we used to go see Mr. Tabuteau in Toulon, and we spent many days with him. This was a vacation, but there were always oboes! I myself remember very well that Tabuteau had a wonderful house in Toulon, and there were always oboe students. It was like an institution -- Tabuteau and his wife.

RG: The last letter Tabuteau wrote before he died was to me. Later Mrs. Tabuteau told us that. The letter was about oboes, of course.

NP: So his last thoughts were of the Lorée oboe?

AG: Yes.